New kid on the block

Posted by: count.d on 03 June 2009

Pic.1.

Posted on: 07 June 2009 by count.d

Sorry I've not posted an internal pic yet Gary. I've been away at the EPSCC (European Plug & Socket Collectors Convention). Short sleeved shirts and moustaches everywhere! Pics will be posted soon.

It's been mounted on the wall and connected for the first time. It's only been a five month wait!

To give it a fair test, I switched off all the gear, unplugged and replugged all connections, then played my usual test records for an hour. My current distribution set up is three double Crabtree sockets mounted to the wall (though only use two) daisy chained with 10mm2 cable, which feed four Powerlines.

My first test track was the wonderful "Most Of The Time" - Bob Dylan - Tell Tale Signs vinyl boxset. If there was ever a track made to show off the wonderful qualities of Naim gear, this is it. The change of pace and dynamics are beautiful. After a couple of hours play, my initial reaction is I'm very, very pleased with the sound. The instant (not burned in) result is similar to the one from adding two Powerlines to the 252/300. It's not as big as adding a Powerline to the Armageddon...... but close. More to follow, when I have time.

It's been mounted on the wall and connected for the first time. It's only been a five month wait!

To give it a fair test, I switched off all the gear, unplugged and replugged all connections, then played my usual test records for an hour. My current distribution set up is three double Crabtree sockets mounted to the wall (though only use two) daisy chained with 10mm2 cable, which feed four Powerlines.

My first test track was the wonderful "Most Of The Time" - Bob Dylan - Tell Tale Signs vinyl boxset. If there was ever a track made to show off the wonderful qualities of Naim gear, this is it. The change of pace and dynamics are beautiful. After a couple of hours play, my initial reaction is I'm very, very pleased with the sound. The instant (not burned in) result is similar to the one from adding two Powerlines to the 252/300. It's not as big as adding a Powerline to the Armageddon...... but close. More to follow, when I have time.

Posted on: 07 June 2009 by 555

Posted on: 08 June 2009 by count.d

Here's a pic. This is before the bolts were shortened in a lathe.

Posted on: 08 June 2009 by count.d

Full internal.

Posted on: 08 June 2009 by SC

Stu - why not ? Seriously ?

Looks the dogs to me...Well done Count.

Even if there's no great sonic gain, it can't be any worse than a series of MK sockets chain ganged and it looks a damn site better...!

Looks the dogs to me...Well done Count.

Even if there's no great sonic gain, it can't be any worse than a series of MK sockets chain ganged and it looks a damn site better...!

Posted on: 08 June 2009 by Adam Meredith

I have no reason to suggest this, apart from unusual perversity, but I would have been tempted to bring the supply in on the centre socket pair.

Plus - the clamped stiff busbar must inhibit the vibrational isolation that the CF is intended to bestow.

All things are simple in retrospect.

Plus - the clamped stiff busbar must inhibit the vibrational isolation that the CF is intended to bestow.

All things are simple in retrospect.

Posted on: 08 June 2009 by count.d

Adam, the supply does go to the centre socket. This was the biggest headache for me to get it there safely and without the cable moving whatsoever (hence the strange looking wood blocks where tie wraps fit). The centre socket supplies equal mains to the two outer sockets.

The unit as a whole, that you see on the internal shot is all solid with no movement from any piece. The carbon backplate is totally isolated from the this unit and mounts to the wall. I only use four sockets, so I would like to push in some sort of plastic pinned blanking plugs (if they exist) into the two spare sockets to take up the tension in the copper receptacles. I can here them rattle if I tap the box.

The unit as a whole, that you see on the internal shot is all solid with no movement from any piece. The carbon backplate is totally isolated from the this unit and mounts to the wall. I only use four sockets, so I would like to push in some sort of plastic pinned blanking plugs (if they exist) into the two spare sockets to take up the tension in the copper receptacles. I can here them rattle if I tap the box.

Posted on: 08 June 2009 by SC

Count - If the input is to the centre socket, why is the cable feed off to the right, just out of interest...?

Steve

Steve

Posted on: 08 June 2009 by 555

Fine design & construction count. Is it me or is it getting hot in here?

Posted on: 08 June 2009 by Occean

Stunning! Fantastic work indeed.

Posted on: 08 June 2009 by Adam Meredith

Google - Child Safety Blanking Plugs (also know as Durex)

Posted on: 08 June 2009 by count.d

quote:Originally posted by SC:

Count - If the input is to the centre socket, why is the cable feed off to the right, just out of interest...?

Steve

My intial intention (and most obvious... and easier) was to feed the cable into the centre of the box to the centre socket...nice short route. However, when I tested this on a dummy box, I couldn't find a method to keep the cable secure inside (with no movement) when I waggled the cable from the outside. I found that once the cable passes under the small carbon clamp, bending it 90 degrees to the left kept the wiring rock solid, no matter how hard I waggle from the outside. Hope this makes sense.

Now you know why it's taken so long!

Posted on: 08 June 2009 by count.d

Thanks Adam, excellent, that looks perfect.

Posted on: 08 June 2009 by Andrew Randle

It certainly looks nice, with good workmanship. However, from a fire perspective, I am concerned about the wood being in contact with the metal conductors.

Andrew Randle

Andrew Randle

Posted on: 08 June 2009 by 555

Posted on: 08 June 2009 by count.d

Andrew, I agree that something like wood and electricity don't initially look like a good couple, but I think you have to look at it logically. The conductors are 2x11mm = 22mm2 which could be roughly rated at 100amps in cable terms. I don't want to get into fuse talk, but let's just say that they could not possibly get even warm in the very worst case scenario. My ,"before the meter unfused", house supply cable from utilities is mounted directly on a wood board, as is my electricity meter and my two consumer units which are all housed in a small wood cupboard...all fitted 2 1/2 years ago by a qualified electrician and a certified.

How many of us have at least one thin plastic extension block in the house, lying on the carpeted wood floor? And these thin plastic extension blocks do burn..try it outside.

How many of us have at least one thin plastic extension block in the house, lying on the carpeted wood floor? And these thin plastic extension blocks do burn..try it outside.

Posted on: 08 June 2009 by BigH47

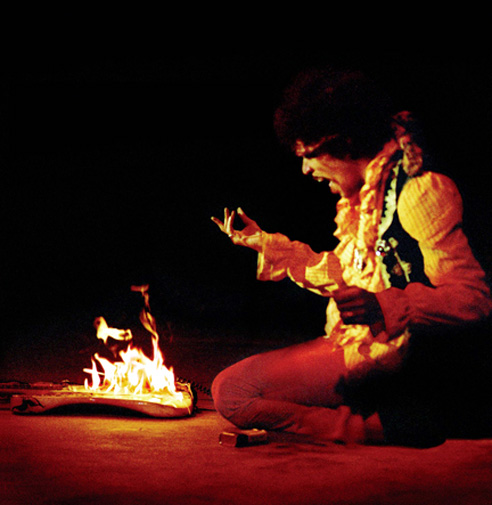

Even Jimi needed lighter fuel to get a blaze. I think you would be unlikely to get those bars hot supplying an arc welder, let alone some hifi bits.

Posted on: 08 June 2009 by 555

I'd happily use one of the counts' blocks, & I'm easily panicked!

When packing up before builders recently I found a semi-melted one.

It was out of sight tucked under a sofa & was supplying a 3KW fire.

quote:thin plastic extension blocks

When packing up before builders recently I found a semi-melted one.

It was out of sight tucked under a sofa & was supplying a 3KW fire.

Posted on: 08 June 2009 by rackkit

I'm surprised that this thread hasn't ended up in the padded cell.

Posted on: 08 June 2009 by Adam Meredith

Isn't it horrible to be right?

Posted on: 08 June 2009 by rackkit

quote:Originally posted by Adam Meredith:

Isn't it horrible to be right?

It's something i've had to live with all my life...

Posted on: 08 June 2009 by DaveBk

Great peice of work count.d - a few questions:

How did you fabricate the copper bus-bars? Cut from copper sheet using a jigsaw and finished by hand or something more sophisticated?

I noticed the sockets had galvanised steel earth links - did you consider replacing these with copper?

I assume you replaced the usual grub screws with bolts so you could tighten them more easily and get a bit more torque?

Thanks.

How did you fabricate the copper bus-bars? Cut from copper sheet using a jigsaw and finished by hand or something more sophisticated?

I noticed the sockets had galvanised steel earth links - did you consider replacing these with copper?

I assume you replaced the usual grub screws with bolts so you could tighten them more easily and get a bit more torque?

Thanks.

Posted on: 09 June 2009 by count.d

Thanks Dave.

I'd love to tell you the copper bars were cut by lasers......

but, I used a jigsaw and finished by hand.

I did think of changing the galvanised earth links, but it's just not possible due to the way the socket has been constructed. Three of the sockets actually have a pure copper direct link, so it's only one that I'm missing out on. I could have bridged the two terminals to exclude the galvanised connection, but I thought it may do more harm than good.

Grub screws have been replaced by bolts, because once the sockets are mounted within the frame, I couldn't get to the grub screws to tighten them. The bolts ends were cut in a lathe to leave a perfectly flat surface to make the wire/bar contact. Bolts were definitely not used to gain more torque, as I don't agree with crushing the copper wire too much, nor stressing the brass ferrules which only have 3-4 threads.

There's a load more info I will write on this little project, with Adams permission.

I'd love to tell you the copper bars were cut by lasers......

but, I used a jigsaw and finished by hand.

I did think of changing the galvanised earth links, but it's just not possible due to the way the socket has been constructed. Three of the sockets actually have a pure copper direct link, so it's only one that I'm missing out on. I could have bridged the two terminals to exclude the galvanised connection, but I thought it may do more harm than good.

Grub screws have been replaced by bolts, because once the sockets are mounted within the frame, I couldn't get to the grub screws to tighten them. The bolts ends were cut in a lathe to leave a perfectly flat surface to make the wire/bar contact. Bolts were definitely not used to gain more torque, as I don't agree with crushing the copper wire too much, nor stressing the brass ferrules which only have 3-4 threads.

There's a load more info I will write on this little project, with Adams permission.

Posted on: 09 June 2009 by DaveBk

Let's hope Adam is in a good mood - I'd like to know as much as possible about this.

Posted on: 09 June 2009 by Adam Meredith

quote:Originally posted by DaveBk:

- I'd like to know as much as possible about this.

No offence but I would think one has probably squeezed the orange of knowledge fairly well dry on the juicer of illustration.